NRTECH

Water Technologies & Solutions fact shee

ZW700B-RMS

rackless module system – ZeeWeed* pressurized ultraf iltration (UF)

Description and use

As a pioneer of membrane technology, veolia leverages decades of research, development, and operational experience to offer one of the most advanced ultrafiltration technology in the market. The ZeeWeed 700B-10060

(Figure 1) line of products contains our SevenBore* fiber technology with an inside-out flow orientation.

The SevenBore fiber is regarded as a leading polyethersulfone (PES) product on the market.

Customers of pressurized UF systems want cost- effective, worry-free solutions that meet their specific needs for the lifetime of their plant. VEOLIA’s engineers have developed a revolutionary solution that meets all these needs.

Fig. 1: ZW700B-RMS

2×6 configuration

NRTECH

product specifications element data

typical process conditions

| Description | ZW700B RMS/UF8/7B/S/0.9/85 |

|---|---|

| Material | Modified PES |

| Type | SevenBore |

| Material housing | PVC |

| Module Surface Area | 85 m2 (914.9 ft2) |

| Material endcap | GFR-Polyamide |

| Permeate connection OD | 2” Victaulic (2” Victaulic) |

| Feed connection OD | 2” Victaulic (2” Victaulic) |

| Housing OD | 250 mm (10 inch) |

| Element OD at endcap | 320 mm (13 inch) |

| Weight | 31.5 kg (69 lbs.) |

| Diameter bores ID | 0.9 mm (0.04 inch) |

| Diameter fiber OD | 3.6 mm (0.16 inch) |

| Description | Measurement |

|---|---|

| Maximum temperature | 40C (104F) |

| Max pressure | 5 bar (72.5 psi) |

| Typical Trans Membrane Pressure (TMP) operation | <1.0 bar (14.5 psi) |

| TMP maximum | 2.5 bar (36 psi) |

| Backwash/forward flush maximum | 250 l/m2h (150 gfd) |

| pH range during operation | 2 to 11 |

cleaning

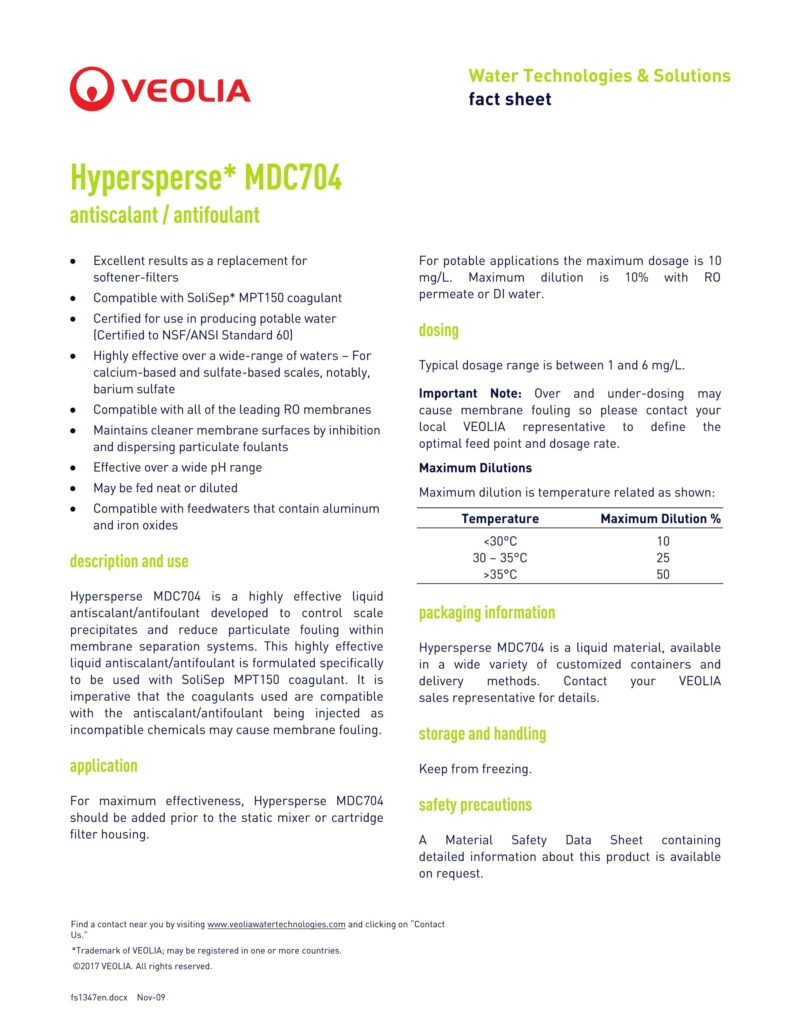

| Description | Measurement |

|---|---|

| Cleaning pH range | 1.0-13.0 |

| Disinfecting Chemicals: Hypochlorite (NaOCl) Hydrogen peroxide |

50 to 200 ppm 100 to 200 ppm |

general properties

• UF membrane – for optimal removal of particulates, bacteria and viruses

• PES membrane fibers with 7 bores – provides high mechanical strength (>10x that of single fibers) and chemical resistance

• Inside-Out filtration – eliminates air scouring step and additional related equipment

storage and handling

All elements are filled with glycerin when new, which is part of the fiber manufacturing and preservation process. Elements must be stored in a dry and normal ventilated location, away from any sources of heat, ignition and direct sunlight in the original packing. The storage temperature must be between 5°C and 35°C (45°F to 91°F).

Find a contact near you by visiting www.veoliawatertechnologies.com and clicking on “Contact Us.” *Trademark ofveolia; may be registered in one or more countries.

©2018 veolia. All rights reserved.

FSufZW700B-RMS_EN RELEASED Jun-18

NRTECH

ZW700B-RMS configurations

RMS with 2 rows of modules (85m2)

RMS with 4 rows of modules (85m2)

NOTE 1: ZW 700B -RMS is not rated for high seismic zones. A seismic kit is available for special acceleration ratings up to 3.0g upon request.