GenGard* GN8168

alkaline cooling water treatment

- Controls deposition and scale with patented technology

- Stable in presence of halogens

- Maximizes protection against deposition and corrosion

- Halogen Stable Azole (HRA) for superior protection of copper or copper alloys

- Minimizes or eliminates acid feed

description and use

GenGard GN8168 is a complete program containing components to control corrosion and a blend of deposit control agents designed to prevent both scale formation and particulate fouling in open recirculating cooling water circuits. The product combines a unique Alkaline Enhanced Chemistry (AEC) for calcium carbonate scale control and a Stress Tolerant Polymer (STP) for complete deposition control with highly supersaturated waters over the alkaline pH range of 7.8 to 9.0 plus.

GenGard GN8168 contains the patented Halogen Resistant Azole (HRA). Unlike conventional azoles, HRA is stable in the presence of halogens such as chlorine and bromine. HRA dramatically improves copper corrosion protection and drastically reduces copper discharge.

VEOLIA’s Alkaline Enhanced Chemistry is a major breakthrough in calcium carbonate scale control. AEC allows high cycles of concentration to be achieved while maintaining heat transfer efficiency. AEC is the only effective non-phosphorus calcium carbonate inhibitor for alkaline pH operation.

Water Technologies & Solutions fact sheet

Unlike conventional phosphonate deposit control additives, AEC and STP are completely halogen stable. Phosphonates are susceptible to breakdown in the presence of halogen (chlorine and bromine), leading to loss of calcium carbonate inhibition. The superior stability of the AEC/STP/HRA combination allows halogen disinfectants to be effectively utilized to maintain system cleanliness and to control Legionella bacteria.

AEC and STP ensure complete deposition control under the most stressful conditions of temperature, flow and water chemistry. The performance of the AEC/STP dispersant package is unmatched by conventional phosphonate/polymer programs.

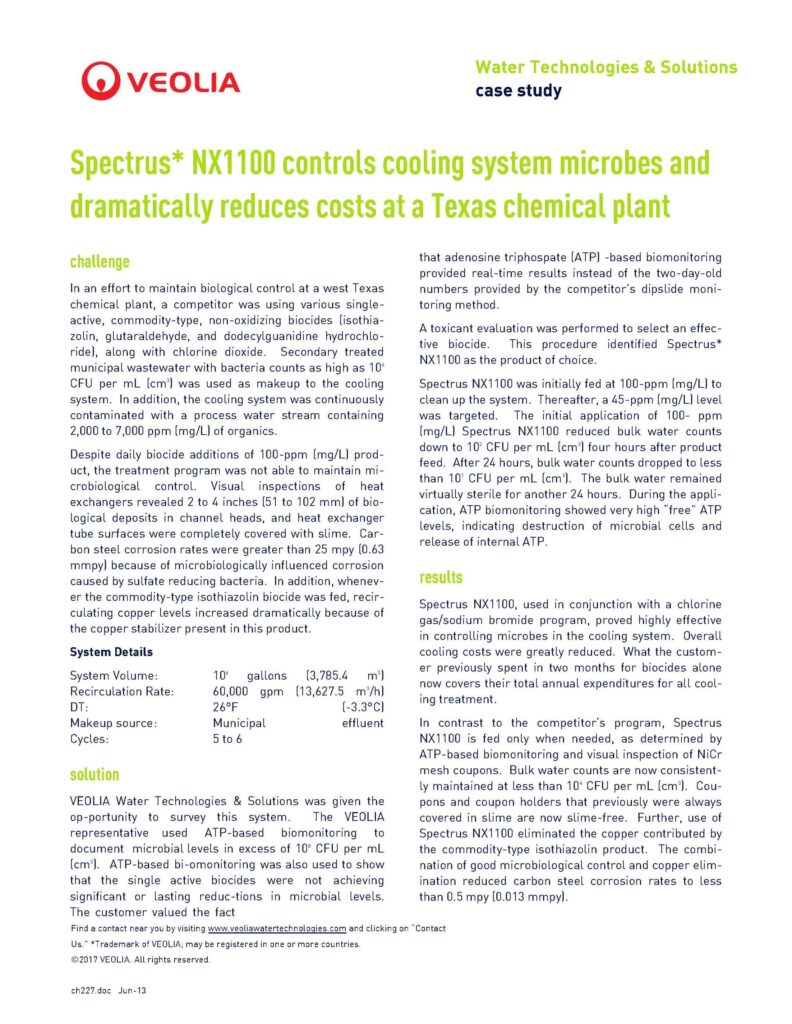

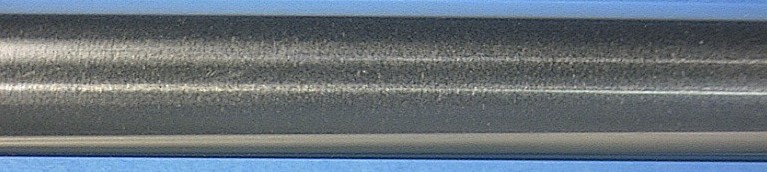

AEC/STP

Conventional Phosphonate/Polymer

Calcium carbonate deposition studies under heat transfer conditions at 135°F (57°C), pH 8.6, 600 ppm Ca Hardness and LSI 2.5 for 6 Days.

treatment and feeding requirements

Proper treatment levels for GenGard GN8168 depend on many factors such as the potential scaling conditions particular to a given installation.

Find a contact near you by visiting www.veoliawatertechnologies.com and clicking on “Contact Us.”

*Trademark of VEOLIA; may be registered in one or more

©2017 VEOLIA. All rights reserved.

countries.

FScGenGardGN8168_EN.docx Oct-10

The product should be used in accordance with control procedures that VEOLIA establishes for a specific application. GenGard GN8168 should be fed to a point in the cooling system where it rapidly mixes with the bulk cooling water.

For best results, GenGard GN8168 should be fed neat (undiluted). Dilutions, if necessary, should only be made with low hardness water.

The feed of GenGard GN8168 is controlled either by a simple and accurate grab sample test or continuously with an on-line monitor. Tanks, pumps, piping, and valves should be made of stainless steel, polyethylene, or PVC.

general properties

Physical properties of GenGard GN8168 are shown on the Material Safety Data Sheet, a copy of which is available on request.

packaging information

GenGard GN8168 is a liquid blend, available in a wide variety of customized containers and delivery methods. Contact your VEOLIA representative for details.

storage

Store GenGard GN8168 at moderate temperatures and protect from freezing. If frozen, thaw completely and mix thoroughly prior to use.

safety precautions

A Material Safety Data Sheet containing detailed information about this product is available on request.

Page 2 FScGenGardGN8168_EN.docx