Total Boiler System Corrosion Inhibitor

- New and improved formulation with goal of providing Polyamine to neutralize amine balance for optimum system protection

- Protects feedwater, boiler, and steam condensate system surfaces against both carbonic acid and dissolved oxygen corrosion

- Provides effective coverage of the entire steam boiler system from a single feedwater injection point

- Offers on-line and off-line corrosion protection

- Reduces total cost of ownership through improved corrosion control

Steamate PAS8040 is a blend of a multifunctional, volatile amine corrosion inhibitor (the “Polyamine” component) and a specific blend of neutralizing amines selected for effective coverage of complex steam distribution systems.

Steamate PAS8040 protects metal surfaces from corrosion via multiple mechanisms. The volatile Polyamine corrosion inhibitor forms a barrier film on all metal surfaces. Thus, the deaerator, feedwater piping, boiler, steam piping, and condensate return piping are all protected from oxygen and carbonic acid corrosion. The product also contains a blend of neutralizing amines, which can neutralize acidic contaminants and elevate the pH of the condensate into the mildly alkaline range, where the protective metal oxides are most stable and adherent.

Improved corrosion control reduces the potential for boiler tube failures by reducing the level of corrosion product ingress from the steam condensate and feedwater circuits and the resulting metal oxide deposition on internal boiler heat transfer surfaces. It also maintains optimum fuel-to-steam efficiency by maintaining clean heat transfer surfaces and minimizes disruptive outages and maintenance costs associated with corrosion-related failures of steam condensate and feedwater piping, economizers, condensers and other heat exchangers, steam traps, and other associated equipment.

Steamate PAS8040 is designed for application to steam boilers. This technology is not approved for use where the steam contacts food products or is used for direct humidification of indoor air.

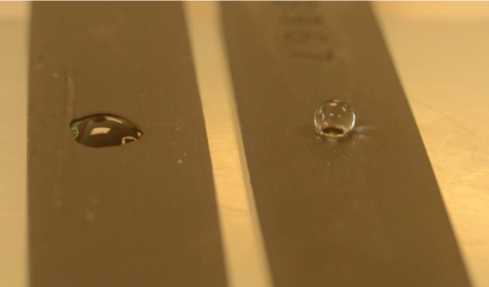

No Filmer Polyamine

Figure 1: Water beading on low carbon steel coupons following Polyamine treatment. Polyamine treatment promotes surface protection.

WATER TECHNOLOGIES

*Trademark of Veolia; may be registered in one or more countries. ©2023 Veolia. All rights reserved. FSbSteamatePAS8040_EN.docx May-23

Treatment and Feeding Requirements

PAS8040 must be fed neat. It is not designed for dilution with water or blending with other boiler treatment products, as dilution will cause destabilization and separation of this liquid blend.

Proper treatment levels for Steamate PAS8040 depend on many factors particular to a given installation. Although the condensate pH is usually maintained in a non-corrosive, mildly alkaline range, the product should be used in accordance with control procedures that Veolia establishes for a specific application.

Physical and Chemical Properties

Physical and chemical properties are shown on the Safety Data Sheet, a copy of which is available on request.

In some cases, a thin waxy layer may appear on top of the product, or the product may look hazy. The thin layer is easily dispersed by mixing and the product becomes clear when heated to 41°C (do not heat above 50°C). The presence of the thin layer or the haziness will not adversely affect the product’s performance.

Steamate PAS8040 is a liquid blend supplied in a variety of consumer packages.

Store Steamate PAS8040 at moderate temperatures (45 to 100°F, 7 to 38°C) in a ventilated location and protect from freezing.

A Safety Data Sheet containing detailed information about Steamate PAS8040 is available on request.

Veolia Water Technologies

Please contact us via:

www.veoliawatertechnologies.com