- Easy to use liquid formula provides complete

single-product boiler treatment

- Includes a fast-acting dissolved oxygen scavenger,

all-polymer internal treatment, volatile steamcondensate corrosion inhibitor, and convenient product tracer

- Patented Boiler Terpolymer (BTP) provides highly effective control of hardness and iron deposition

- Reduces potential for boiler failures due to dissolved oxygen pitting, waterside deposits, and carbonic acid corrosion

- Enhanced rejection of iron, magnesium, and silica contaminants to the blowdown translates to cleaner, more efficient boilers

- All the ingredients in Solus MCA42 are approved for FDA 21CFR173.310 and Health Canada – boiler water additives for use in the preparation of steam that will contact food, up to a maximum level of 4167 ppm in the boiler water. Solus MCA42 is also approved as NSF-USDA G6.

Solus MCA42 is an advanced, multicomponent formulation that includes an oxygen scavenger, advanced all-polymer internal treatment, neutralizing amine, and easily tested product tracer. It provides a complete boiler system treatment in a single, easily fed liquid concentrate. Solus MCA42 is designed to be used in systems that have a thermal deaerator or where the boiler feedwater is at least 90oC.

The BTP contained in Solus MCA42 is multifunctional and limits deposits through its ability to:

- Maintain incoming feedwater contaminants, such as calcium and magnesium, in soluble form for efficient rejection to the boiler blowdown;

- Distort crystal growth, thus reducing the size of particles that are formed;

- Alter the surface charge of the suspended particles as well as the boiler tube surfaces, reducing the particleparticle attraction and the attraction between particles and the boiler tube walls.

This results in significantly reduced scale potential and cleaner heat transfer surfaces, especially during upsets in control or variations in feedwater hardness.

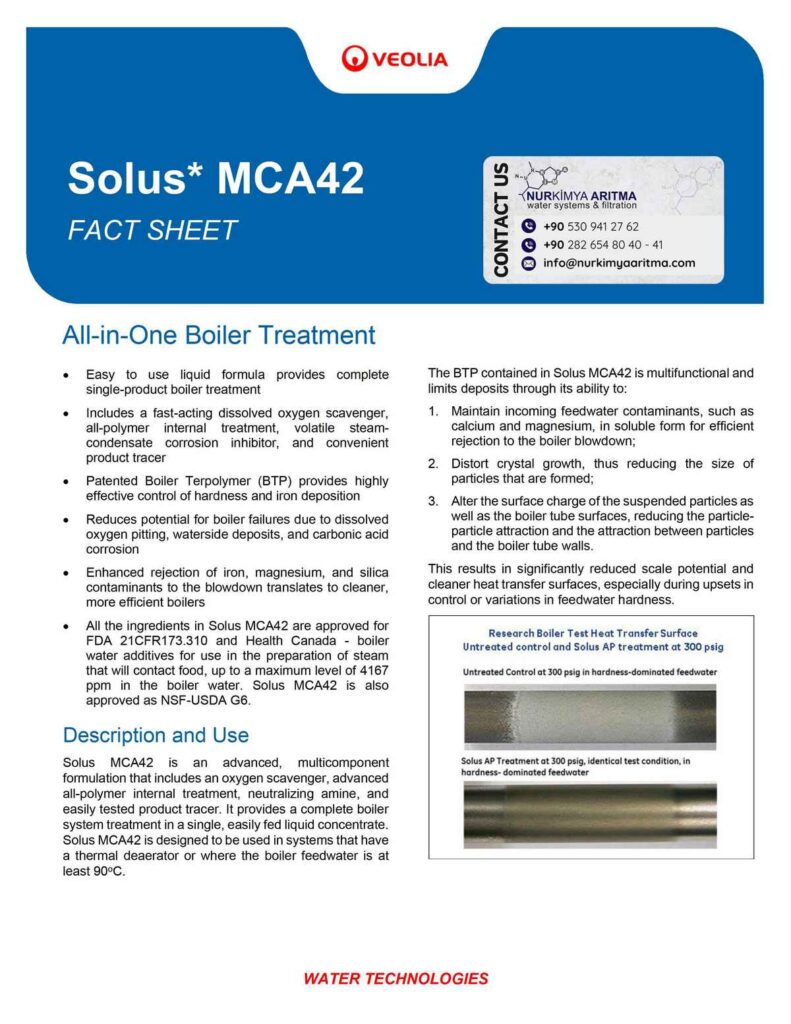

Research Boiler Test Heat Transfer Surface Untreated control and Solus AP treatment at 300 psig

Untreated Control at 300 psig in hardness-dominated feedwater

Solus AP Treatment at 300 psig, identical test condition, in hardness- dominated feedwater

WATER TECHNOLOGIES

*Trademark of Veolia; may be registered in one or more countries. ©2022 Veolia. All rights reserved. AM-FSbSolusMCA42_EN.docx Jan-19

Treatment and Feeding Requirements

Feed point – The preferred feed point for Solus MCA42 is the feedwater tank, hotwell, or deaerator storage section via a 304 or 316 stainless steel injection quill located below the operating waterline of the vessel.

This feed location provides valuable residence time in the vessel, allowing the scavenger in Solus MCA42 to react with and remove dissolved oxygen prior to reaching the boiler feedwater piping, pumps, economizer, and boiler.

Feed rate – The initial feed rate calculations for Solus MCA42 are based on the level of dissolved oxygen or total hardness and iron in the boiler feedwater. Feed rate determination is achieved by measuring the boiler water sulphite residual and molybdate level.

Proper treatment levels for Solus MCA42 depend on many factors specific to a given installation. The product should be used in accordance with the control procedures that Veolia establishes for a specific application.

Feed rate control is ideally automated based on a proportional ratio to steam production or feedwater flow.

Dilution – Solus MCA42 may be fed neat or diluted to any convenient strength with good quality condensate, demineralized water, or feedwater.

Equipment – Chemical feed should be through a 304 or 316 stainless steel injection nozzle.

Please reference the Material Safety Data Sheet (MSDS) for the physical properties of Solus MCA42.

Solus MCA42 is available in a wide variety of customized containers and delivery methods. Contact your Veolia representative for details.

Maintain storage temperature of minimum 10°C (50oF) to minimize risk for sulphite crystallisation. Protect from freezing. If frozen, thaw completely and mix thoroughly prior to use.

Avoid direct exposure to sunlight and store in a shaded area at a maximum of 38°C (100°F). Reduce exposure to atmospheric oxygen.

Consideration should be given to installing flush/dilution water lines to day tanks and feed systems for removal of sulphite crystals that may develop with time.

Please reference the MSDS for detailed safety information regarding MCA42.

Veolia Water Technologies

Please contact us via:

www.veoliawatertechnologies.com

- Easy to use liquid formula provides complete

single-product boiler treatment

- Includes a fast-acting dissolved oxygen scavenger,

all-polymer internal treatment, volatile steamcondensate corrosion inhibitor, and convenient product tracer

- Patented Boiler Terpolymer (BTP) provides highly effective control of hardness and iron deposition

- Reduces potential for boiler failures due to dissolved oxygen pitting, waterside deposits, and carbonic acid corrosion

- Enhanced rejection of iron, magnesium, and silica contaminants to the blowdown translates to cleaner, more efficient boilers

- All the ingredients in Solus MCA42 are approved for FDA 21CFR173.310 and Health Canada – boiler water additives for use in the preparation of steam that will contact food, up to a maximum level of 4167 ppm in the boiler water. Solus MCA42 is also approved as NSF-USDA G6.

Solus MCA42 is an advanced, multicomponent formulation that includes an oxygen scavenger, advanced all-polymer internal treatment, neutralizing amine, and easily tested product tracer. It provides a complete boiler system treatment in a single, easily fed liquid concentrate. Solus MCA42 is designed to be used in systems that have a thermal deaerator or where the boiler feedwater is at least 90oC.

The BTP contained in Solus MCA42 is multifunctional and limits deposits through its ability to:

- Maintain incoming feedwater contaminants, such as calcium and magnesium, in soluble form for efficient rejection to the boiler blowdown;

- Distort crystal growth, thus reducing the size of particles that are formed;

- Alter the surface charge of the suspended particles as well as the boiler tube surfaces, reducing the particleparticle attraction and the attraction between particles and the boiler tube walls.

This results in significantly reduced scale potential and cleaner heat transfer surfaces, especially during upsets in control or variations in feedwater hardness.

Research Boiler Test Heat Transfer Surface Untreated control and Solus AP treatment at 300 psig

Untreated Control at 300 psig in hardness-dominated feedwater

Solus AP Treatment at 300 psig, identical test condition, in hardness- dominated feedwater

WATER TECHNOLOGIES

*Trademark of Veolia; may be registered in one or more countries. ©2022 Veolia. All rights reserved. AM-FSbSolusMCA42_EN.docx Jan-19

Treatment and Feeding Requirements

Feed point – The preferred feed point for Solus MCA42 is the feedwater tank, hotwell, or deaerator storage section via a 304 or 316 stainless steel injection quill located below the operating waterline of the vessel.

This feed location provides valuable residence time in the vessel, allowing the scavenger in Solus MCA42 to react with and remove dissolved oxygen prior to reaching the boiler feedwater piping, pumps, economizer, and boiler.

Feed rate – The initial feed rate calculations for Solus MCA42 are based on the level of dissolved oxygen or total hardness and iron in the boiler feedwater. Feed rate determination is achieved by measuring the boiler water sulphite residual and molybdate level.

Proper treatment levels for Solus MCA42 depend on many factors specific to a given installation. The product should be used in accordance with the control procedures that Veolia establishes for a specific application.

Feed rate control is ideally automated based on a proportional ratio to steam production or feedwater flow.

Dilution – Solus MCA42 may be fed neat or diluted to any convenient strength with good quality condensate, demineralized water, or feedwater.

Equipment – Chemical feed should be through a 304 or 316 stainless steel injection nozzle.

Please reference the Material Safety Data Sheet (MSDS) for the physical properties of Solus MCA42.

Solus MCA42 is available in a wide variety of customized containers and delivery methods. Contact your Veolia representative for details.

Maintain storage temperature of minimum 10°C (50oF) to minimize risk for sulphite crystallisation. Protect from freezing. If frozen, thaw completely and mix thoroughly prior to use.

Avoid direct exposure to sunlight and store in a shaded area at a maximum of 38°C (100°F). Reduce exposure to atmospheric oxygen.

Consideration should be given to installing flush/dilution water lines to day tanks and feed systems for removal of sulphite crystals that may develop with time.

Please reference the MSDS for detailed safety information regarding MCA42.

Veolia Water Technologies

Please contact us via:

www.veoliawatertechnologies.com