All-Polymer Internal Boiler Treatment

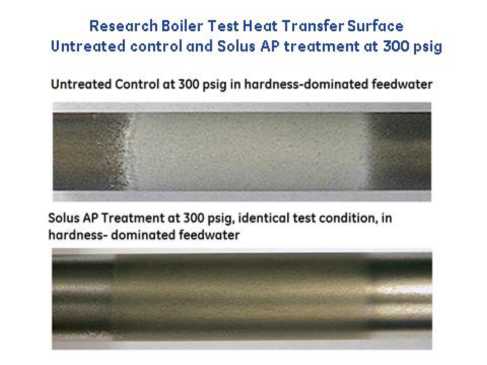

- Patented Boiler Terpolymer (BTP) provides highly effective control of hardness and iron deposition

- All-polymer treatment reduces the potential for boiler tube failures due to waterside deposits

- Enhanced rejection of iron, calcium, magnesium, and silica contaminants to the blowdown translates to cleaner, more efficient boilers

- Easily tested product tracer for convenient feed rate control

- FDA 21CFR173.310 and Health Canada approved for treatment of steam that may contact food. NSF-USDA G6 and Kosher.

Solus AP26 is the latest technological innovation in boiler scale control and internal treatment from Veolia. This all-polymer technology is designed to meet the deposit control performance needs of modern low-to-intermediate pressure steam boilers (up to 600 psig/41 barg). It is a cost-effective, easy- to-use treatment in a stable, liquid formulation.

The BTP contained in Solus AP26 is multifunctional and limits deposits through its ability to:

- Maintain incoming feedwater contaminants, such as calcium and magnesium, in soluble form for efficient rejection to the boiler blowdown;

- Distort crystal growth, thus reducing the size of particles that are formed;

- Alter the surface charge of the suspended particles as well as the boiler tube surfaces, reducing the particle-particle attraction and the attraction between particles and the boiler tube walls.

This results in significantly reduced scale potential and cleaner heat transfer surfaces, especially during upsets in control or variations in feedwater hardness.

Treatment and Feeding Requirements

Feed Point – The product is recommended to be fed to the boiler feedwater downstream of the boiler feed pumps. Feeding directly to the deaerator is also acceptable if the feedwater is not used for attemperation. The product should be significantly diluted (<5% solution) if injecting directly to the boiler.

Feed Rate – Proper treatment levels for Solus AP26 depend on many factors specific to a given installation. The product should be used in accordance with the control procedures that Veolia establishes for a specific application.

Solus AP26

Dilution – Solus AP26 may be fed neat or diluted to any convenient strength with good quality condensate, demineralized water, or feedwater. Dilution using softened water is not preferred but usually acceptable.

Equipment – Chemical feed should be through a 304 or 316 stainless steel injection nozzle.

Regulatory – Solus AP26 is approved per FDA 21CFR173.310 and Health Canada for treatment of steam that may contact food to a maximum dosage of 1282 ppm in the boiler water. It is also approved per NSF-USDA G6 and is Kosher.

General Properties

Please reference the Safety Data Sheet (SDS) for the physical properties of Solus AP26.

*Trademark of Veolia; may be registered in one or more countries. ©2024 Veolia. All rights reserved. AM-FSbSolusAP26_EN.docx May-24

Solus AP26 is available in a wide variety of customized containers and delivery methods. Contact your Veolia representative for details.

Store Solus AP26 at a moderate temperature and protect from freezing. If frozen, thaw completely and mix thoroughly before use.

Please reference the SDS for detailed safety information regarding Solus AP26.