ROSave.Z* FACT SHEET

Z.Plex* technology depth filter for reverse osmosis pre-filtration

Specifications

Table 1: Specifications and performance information

| Ratings | 1, 5 microns (nominal) |

| Inner Diameter (nominal) | 1 in (2.5 cm) |

| Outer Diameter | 2.5 in (6.4 cm) |

| Lengths | |

| 9 3/4 in (24.8 cm) | 20 in (50.8 cm) |

| 9 7/8 in (25.1 cm) | 29 1/4 in (74.3 cm) |

| 10 in (25.4 cm) | 30 in (76.2 cm) |

| 19 1/2 in (49.5 cm) | 40 in (101.6 cm) |

| Longer lengths up to 70 in may be available upon request | |

| Materials of Construction | |

| Filter Media | Polypropylene |

| Adapters | Polypropylene |

| Elastomer | Buna, EPDM, Silicone, Viton1, Santoprene2

(flat gasket only) |

| Performance Conditions | |

| Maximum pressure drop: | |

| 35 psid (2.4 bar) @ 77°F (25°C) | |

| Recommended change-out pressure drop: | |

| 20 psid (1.4 bar) @ 77°F (25°C) | |

Features and Benefits

- Engineered specifically for reverse osmosis pretreatment and suitable for many pure water applications

- Depth filter traps particles throughout the media

- True depth media offers longer filter lifetime

- Very low pressure drop and flow resistance

- Thermally bonded construction and mel-bonded end adaption

Applications

- Reverse osmosis pre-filtration for Veolia RO systems and universal equipment

- Beverage

- Electronics

- Pre/post DI or active carbon

Efficiency Information

Table 2: Removal efficiency based on a modified ASTM 795 test procedure

| Micron Rating | Removal rating (µm) at various efficiencies | ||

| 90.0% | 99.0% | 99.9% | |

| 1 µm | Efficiency of nominal filters varies by application.

See note for information on nominal filter efficiency3 |

||

WATER TECHNOLOGIES

Quality

ROSave.Z filters are manufactured under a quality management system that has been certified to meet ISO 9001 standards. Each filter is assigned a lot code to ensure traceability of the data and materials used in the manufacturing process.

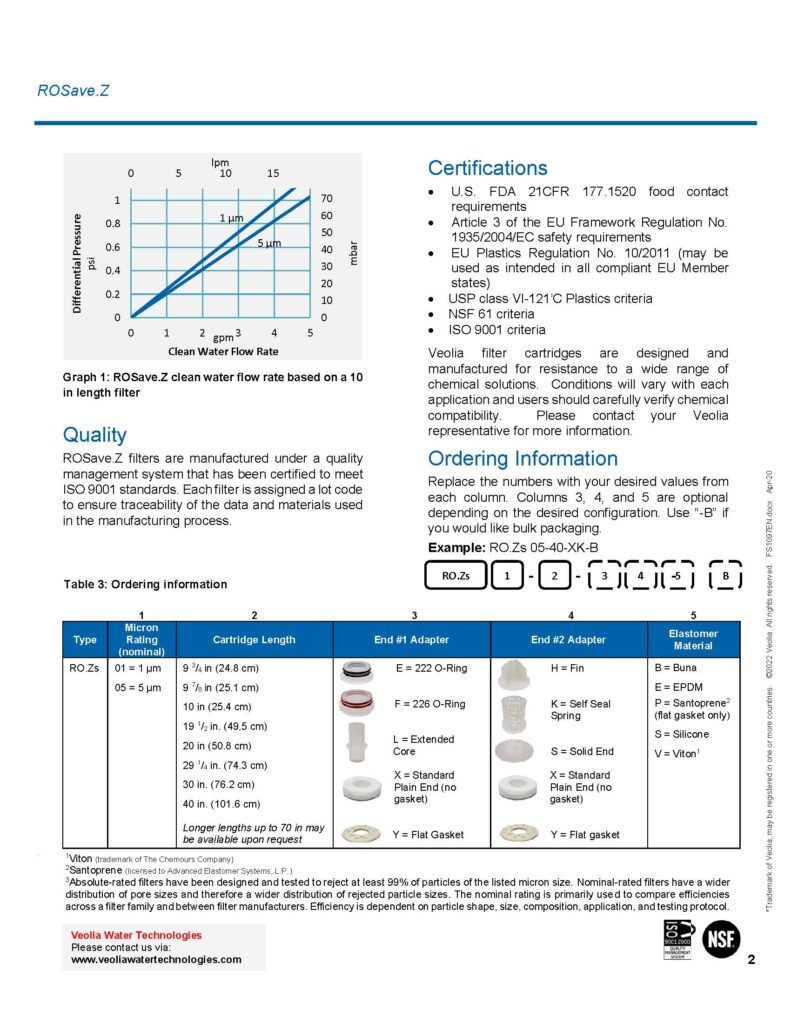

Table 3: Ordering information

Certifications

- U.S. FDA 21CFR 177.1520 food contact requirements

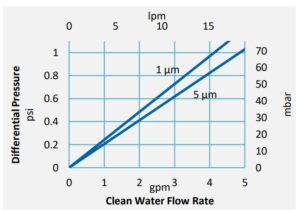

- Article 3 of the EU Framework Regulation No. 1935/2004/EC safety requirements mbar

- EU Plastics Regulation No. 10/2011 (may be used as intended in all compliant EU Member states)

- USP class VI-121’C Plastics criteria

- NSF 61 criteria

- ISO 9001 criteria

Veolia filter cartridges are designed and manufactured for resistance to a wide range of chemical solutions. Conditions will vary with each application and users should carefully verify chemical compatibility. Please contact your Veolia representative for more information.

Ordering Information

*Trademark of Veolia; may be registered in one or more countries. ©2022 Veolia. All rights reserved. FS1097EN.docx Apr-20

Replace the numbers with your desired values from each column. Columns 3, 4, and 5 are optional depending on the desired configuration. Use “-B” if you would like bulk packaging.

Example: RO.Zs 05-40-XK-B

– ![]()

| 1 | 2 | 3 | 4 | 5 | |

| Type | Micron Rating

(nominal) |

Cartridge Length | End #1 Adapter | End #2 Adapter | Elastomer Material |

| RO.Zs | 01 = 1 µm

05 = 5 µm |

9 3/4 in (24.8 cm)

9 7/8 in (25.1 cm) |

E = 222 O-Ring

L = Extended Core X = Standard Plain End (no gasket)

|

H = Fin

|

B = Buna

E = EPDM |

| 10 in (25.4 cm)

19 1/2 in. (49.5 cm) |

K = Self Seal Spring

|

P = Santoprene2 (flat gasket only)

S = Silicone |

|||

| 20 in (50.8 cm)

29 1/4 in. (74.3 cm) 30 in. (76.2 cm) 40 in. (101.6 cm) |

S = Solid End

|

V = Viton1 | |||

| Longer lengths up to 70 in may be available upon request |

1Viton (trademark of The Chemours Company)

2Santoprene (licensed to Advanced Elastomer Systems, L.P.)

3Absolute-rated filters have been designed and tested to reject at least 99% of particles of the listed micron size. Nominal-rated filters have a wider

distribution of pore sizes and therefore a wider distribution of rejected particle sizes. The nominal rating is primarily used to compare efficiencies

across a filter family and between filter manufacturers. Efficiency is dependent on particle shape, size, composition, application, and testing protocol.

F = 226 O-Ring

F = 226 O-Ring

X = Standard Plain End (no gasket)

X = Standard Plain End (no gasket)