Membrane cleaner for inorganics

Kleen MCT113 is a unique and superior low pH liquid formulation designed specifically to remove Fe, Al, Mn metal hydroxides, calcium carbonate, and calcium phosphate other similar scales from reverse osmosis (RO), nanofiltration (NF) and ultrafiltration (UF) membranes. This highly effective product provides superior cleaning resulting in longer system running time.

Kleen MCT113 offers the following features:

- Suitable for use with all thin film composite or cellulose acetate membranes.

- Buffered to maintain a pH of 3.0 ± 0.5 over a range of dilutions.

• Best use concentration is at 2% solution strength • Liquid cleaner, which allows shorter mixing time. • No adverse effects with repeated use.

- Non-foaming formulation.

Kleen MCT113 should be used in combination with high pH cleaning step products for example, MCT515(liquid) or Kleen MCT411(Powder) for optimum results.

Treatment and Feeding Requirements

Dilution

The typical dilution ratio for Kleen MCT113 is in the range of 1-3% in proportion to the total volume of the cleaning system inclusive of:

- Cleaning tank and all interconnecting pipe work

- Filtration and membrane pressure vessels and

membrane elements.

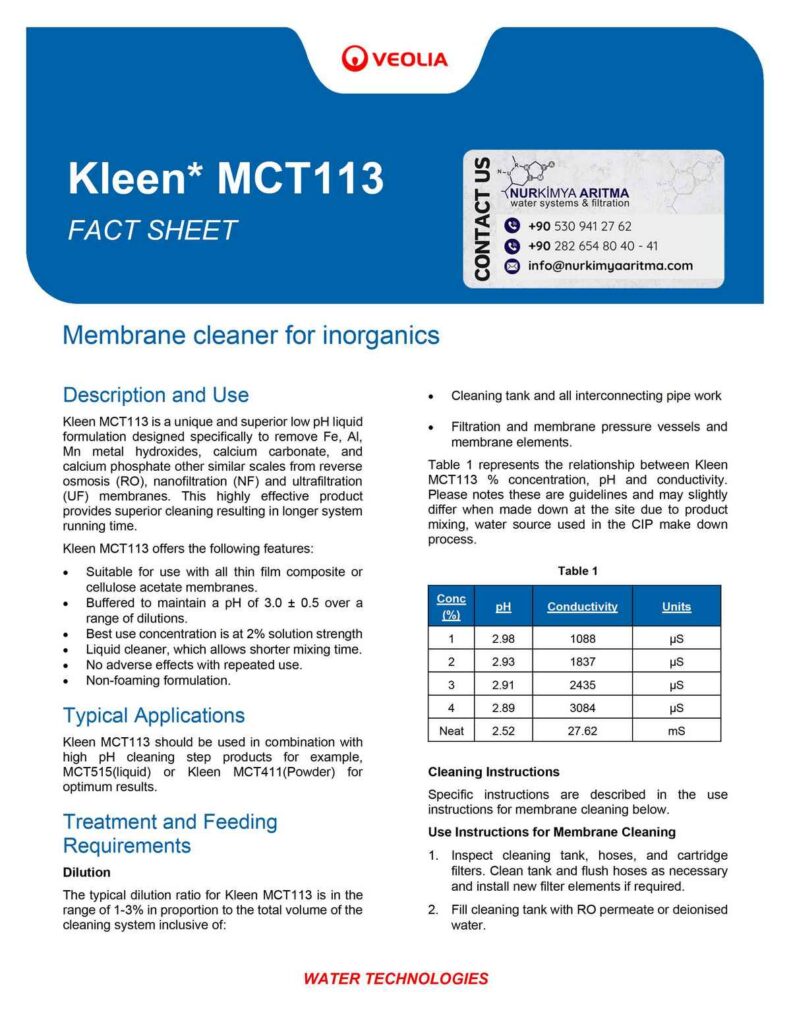

Table 1 represents the relationship between Kleen MCT113 % concentration, pH and conductivity. Please notes these are guidelines and may slightly differ when made down at the site due to product mixing, water source used in the CIP make down process.

Table 1

| Conc (%) | pH | Conductivity | Units |

| 1 | 2.98 | 1088 | ms |

| 2 | 2.93 | 1837 | MS |

| 3 | 2.91 | 2435 | MS |

| 4 | 2.89 | 3084 | MS |

| Neat | 2.52 | 27.62 | mS |

Cleaning Instructions

Specific instructions are described in the use instructions for membrane cleaning below.

Use Instructions for Membrane Cleaning

- Inspect cleaning tank, hoses, and cartridge filters. Clean tank and flush hoses as necessary and install new filter elements if required.

- Fill cleaning tank with RO permeate or deionised water.

WATER TECHNOLOGIES

*Trademark of Veolia; may be registered in one or more countries. ©2022 Veolia. All rights reserved. FSmcKleenMCT113_EN.docx Jan-19

- Slowly add the calculated quantity of Kleen MCT113 to the cleaning tank and mix thoroughly by recirculating the solution through the cleaning pump.

- Check cleaning solution temperature and pH and adjust as necessary to provide the optimum cleaning temperature and pH (2.5 – 3.5). Do not exceed membrane manufacturers specifications.

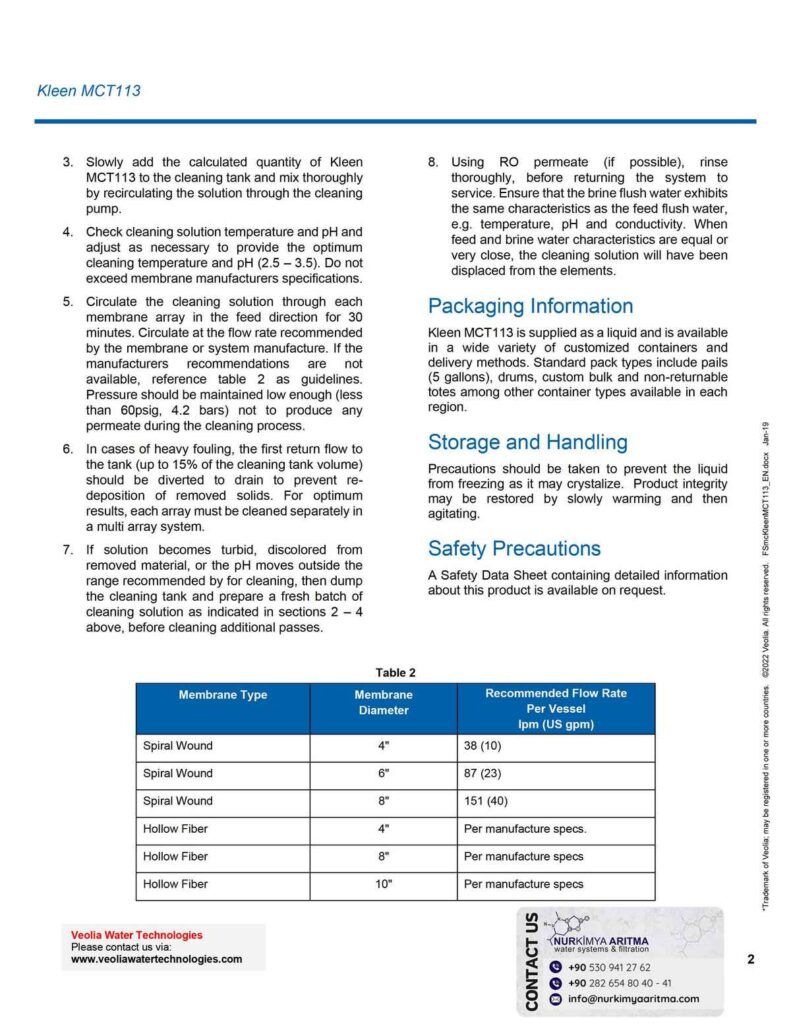

- Circulate the cleaning solution through each membrane array in the feed direction for 30 minutes. Circulate at the flow rate recommended by the membrane or system manufacture. If the manufacturers recommendations are not available, reference table 2 as guidelines. Pressure should be maintained low enough (less than 60psig, 4.2 bars) not to produce any permeate during the cleaning process.

- In cases of heavy fouling, the first return flow to the tank (up to 15% of the cleaning tank volume) should be diverted to drain to prevent redeposition of removed solids. For optimum results, each array must be cleaned separately in a multi array system.

- If solution becomes turbid, discolored from removed material, or the pH moves outside the range recommended by for cleaning, then dump the cleaning tank and prepare a fresh batch of cleaning solution as indicated in sections 2 – 4 above, before cleaning additional passes.

- Using RO permeate (if possible), rinse thoroughly, before returning the system to service. Ensure that the brine flush water exhibits the same characteristics as the feed flush water, e.g. temperature, pH and conductivity. When feed and brine water characteristics are equal or very close, the cleaning solution will have been displaced from the elements.

Kleen MCT113 is supplied as a liquid and is available in a wide variety of customized containers and delivery methods. Standard pack types include pails (5 gallons), drums, custom bulk and non-returnable totes among other container types available in each region.

Precautions should be taken to prevent the liquid from freezing as it may crystalize. Product integrity may be restored by slowly warming and then agitating.

A Safety Data Sheet containing detailed information about this product is available on request.

| Membrane Type | Membrane Diameter | Recommended Flow Rate Per Vessel lpm (US gpm) |

|---|---|---|

| Spiral Wound | 4″ | 38 (10) |

| Spiral Wound | 6″ | 87 (23) |

| Spiral Wound | 8″ | 151 (40) |

| Hollow Fiber | 4″ | Per manufacture specs. |

| Hollow Fiber | 8″ | Per manufacture specs |

| Hollow Fiber | 10″ | Per manufacture specs |

Table 2

Veolia Water Technologies

Please contact us via:

www.veoliawatertechnologies.com