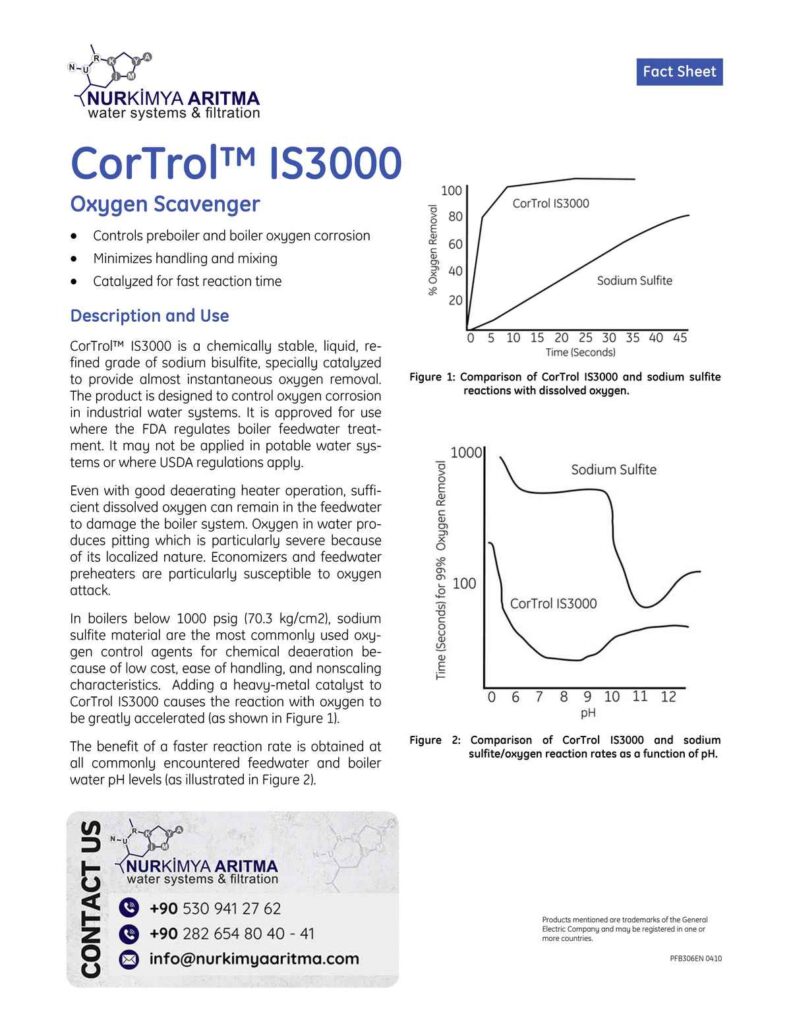

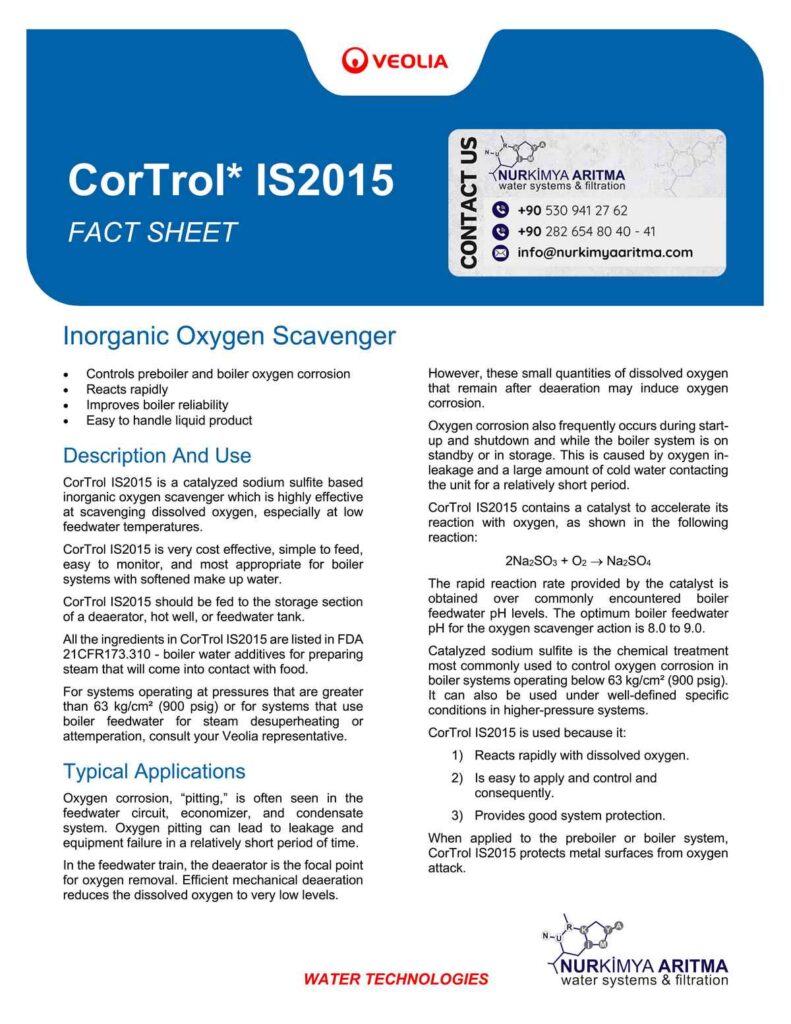

Figure 1: Comparison of CorTrol IS3000 and sodium sulfite reactions with dissolved oxygen.

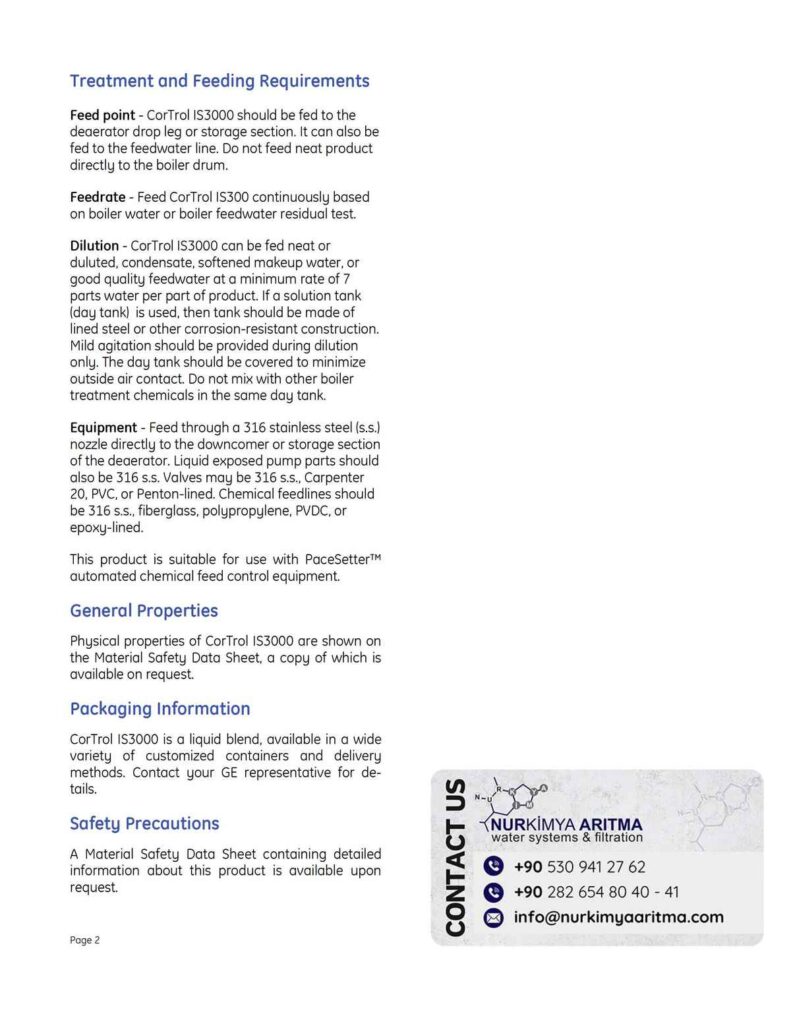

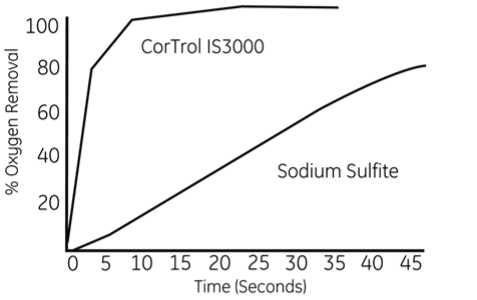

Figure 2: Comparison of CorTrol IS3000 and sodium sulfite/oxygen reaction rates as a function of pH.

Oxygen Scavenger

- Controls preboiler and boiler oxygen corrosion

- Minimizes handling and mixing

- Catalyzed for fast reaction time

CorTrol™ IS3000 is a chemically stable, liquid, refined grade of sodium bisulfite, specially catalyzed to provide almost instantaneous oxygen removal. The product is designed to control oxygen corrosion in industrial water systems. It is approved for use where the FDA regulates boiler feedwater treatment. It may not be applied in potable water systems or where USDA regulations apply.

Even with good deaerating heater operation, sufficient dissolved oxygen can remain in the feedwater to damage the boiler system. Oxygen in water produces pitting which is particularly severe because of its localized nature. Economizers and feedwater preheaters are particularly susceptible to oxygen attack.

In boilers below 1000 psig (70.3 kg/cm2), sodium sulfite material are the most commonly used oxygen control agents for chemical deaeration because of low cost, ease of handling, and nonscaling characteristics. Adding a heavy-metal catalyst to CorTrol IS3000 causes the reaction with oxygen to be greatly accelerated (as shown in Figure 1).

The benefit of a faster reaction rate is obtained at all commonly encountered feedwater and boiler water pH levels (as illustrated in Figure 2).

PFB306EN 0410

Treatment and Feeding Requirements

Feed point – CorTrol IS3000 should be fed to the deaerator drop leg or storage section. It can also be fed to the feedwater line. Do not feed neat product directly to the boiler drum.

Feedrate – Feed CorTrol IS300 continuously based on boiler water or boiler feedwater residual test.

Dilution – CorTrol IS3000 can be fed neat or duluted, condensate, softened makeup water, or good quality feedwater at a minimum rate of 7 parts water per part of product. If a solution tank (day tank) is used, then tank should be made of lined steel or other corrosion-resistant construction. Mild agitation should be provided during dilution only. The day tank should be covered to minimize outside air contact. Do not mix with other boiler treatment chemicals in the same day tank.

Equipment – Feed through a 316 stainless steel (s.s.) nozzle directly to the downcomer or storage section of the deaerator. Liquid exposed pump parts should also be 316 s.s. Valves may be 316 s.s., Carpenter 20, PVC, or Penton-lined. Chemical feedlines should be 316 s.s., fiberglass, polypropylene, PVDC, or epoxy-lined.

This product is suitable for use with PaceSetter™ automated chemical feed control equipment.

Physical properties of CorTrol IS3000 are shown on the Material Safety Data Sheet, a copy of which is available on request.

CorTrol IS3000 is a liquid blend, available in a wide variety of customized containers and delivery methods. Contact your GE representative for details.

A Material Safety Data Sheet containing detailed information about this product is available upon request.